What is entry level automation and who is it for?

Essentially, entry-level packaging automation is a gap filler for the company that may not need a fully-automated line but could benefit from the utility, convenience, and accuracy associated with automating at least some of the smaller tasks.

From ecommerce to brick-and-mortar retail to medical and pharmaceutical to bakery and service… these have tasks that could be automated. Tasks such as opening and closing bags, applying labels, and more. Entry-level packaging automation is very similar to standard packaging automation, except the functions tend to be a bit more basic.

It can feel overwhelming as demand for your product increases if you don’t have the framework in place to handle it. Packaging problems could arise that will eventually foil all that hard-earned growth.

How do you know that it’s time to take that step toward researching the proper tools that could not only preserve the integrity of your business but catapult it to the next level?

5 problems and solutions where entry-level automation can help

- Packing too slow –> bag openers

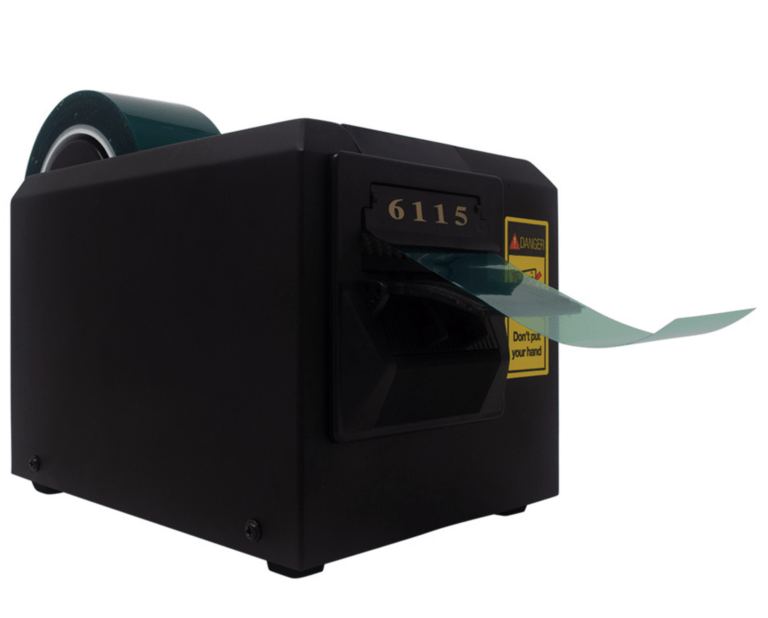

- Shipping too slow –> tape dispensers

- Growing product line –> tagging guns

- Overwhelmed employees –> twist tie machines

- Increasing labor costs –> label dispensers

To expedite the packaging process and reduce mundane and repetitive tasks for the worker, consider automated bag openers. They operate by inflating a poly bag and allowing a person to quickly slide in a product, while a bag closing device seals a bag shut with heat, tape, twist ties, or something else.

Another helpful tool is an automated tape dispenser. Speed up the sealing of your shipments with a robotic version that can dispense pre-cut and pre-determined lengths. This benefits your company by reducing material waste and minimizing the amount of time needed to unwind and tear tape by hand to get those packages out the door for shipping.

Your product line is growing… yay! This can also mean that attention to detail is compromised, as well as your reputation. More products to pack or label can lead to less time or people to process them. Tagging guns quickly attach any labels or marketing materials with the pull of a trigger.

Repetitive motions for employees such as opening and closing boxes and bags, wrapping and twisting wires or string, etc can take a toll and cause overwhelm. Twist tie machines increase productivity and can reduce instances of application flaws or inconsistencies. They quickly wrap up and close the opening of a bag, or secure a group of items tightly together.

The increase in demand and new products you’re offering is a great sign of growth, but also a sign of increased labor costs. You’re glad to grow, but your budget might not be able to handle the extra man hours, especially in the early stages. Another example of entry-level automation that will speed up your packing efforts is adding a label dispenser. They can quickly print your label, peel from their backing, and apply it directly to a box or bag.

One last thing to consider when looking into entry-level automation… your competition is doing it! Everyone is looking to cut costs and increase both productivity and profit without sacrificing quality.